Testing Facilities in the Laboratory of the Department of Steel Structures and Structural Mechanics

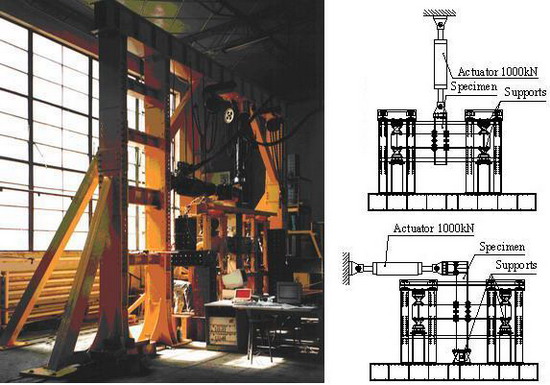

Reaction frame and the hydraulic actuator

The testing frame is equipped with two hydraulic actuators QUIRI with the following characteristics:

| Capacity | Actuator1: | 422 kN under dynamic loading |

| 563 kN under static loading | ||

| Actuator 2: | 950 kN under dynamic loading | |

| 1267 kN under static loading |

- Stroke: +/-200 mm

- Computer operation.

- Displacement or force control.

- Predefined, as well as user defined loading procedures.

- Built-in displacement and force transducers.

Data acquisition systems

HP3852A data logger with the following characteristics:- 40 de channels for transducers, as follows:

- 30 channels for resistive transducers

- 4 analogous channels

- 6 channels for inductive transducers

- 50 channels for strain gauges

ESAM TRAVELLER high-speed data acquisition and data processing system with 64 de channels.

Transducers

- Displacement transducers

- Inclinometers

- Load cells

Universal testing machine TESTWELL/UTS

- hydraulic grips

- tension and compression tests

- capacity: 250 kN

- computer aided control, acquisition and post processing of results

Testing frame for buckling

QUIRI hydraulic jacks of 100 kN (2 pcs), 200 kN

(2 pcs), 450 kN (2 pcs), 750 kN (1 pc), 1100 kN (1 pc)

3D measurement system for contour, displacement and deformation Vic 3D

Based on digital image correlation techniques and stereoscopic principle of the setup of two cameras, the object contour, displacement and strain is measured contactless

- optical contactless measurement of 3D shape, displacements, deformations and strains

- point to point accuracy of displacement: 0.01 pixel

- point to point strain accuracy: 0.02%

- patial resolution 1392*1024 pixel / 10 Hz

Pendulum impact testing machine

- 300 J pendulum

- Temperature chamber (-60 ... +80C)

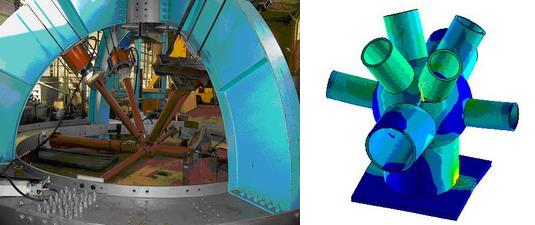

Testing frame for joints in spatial structures